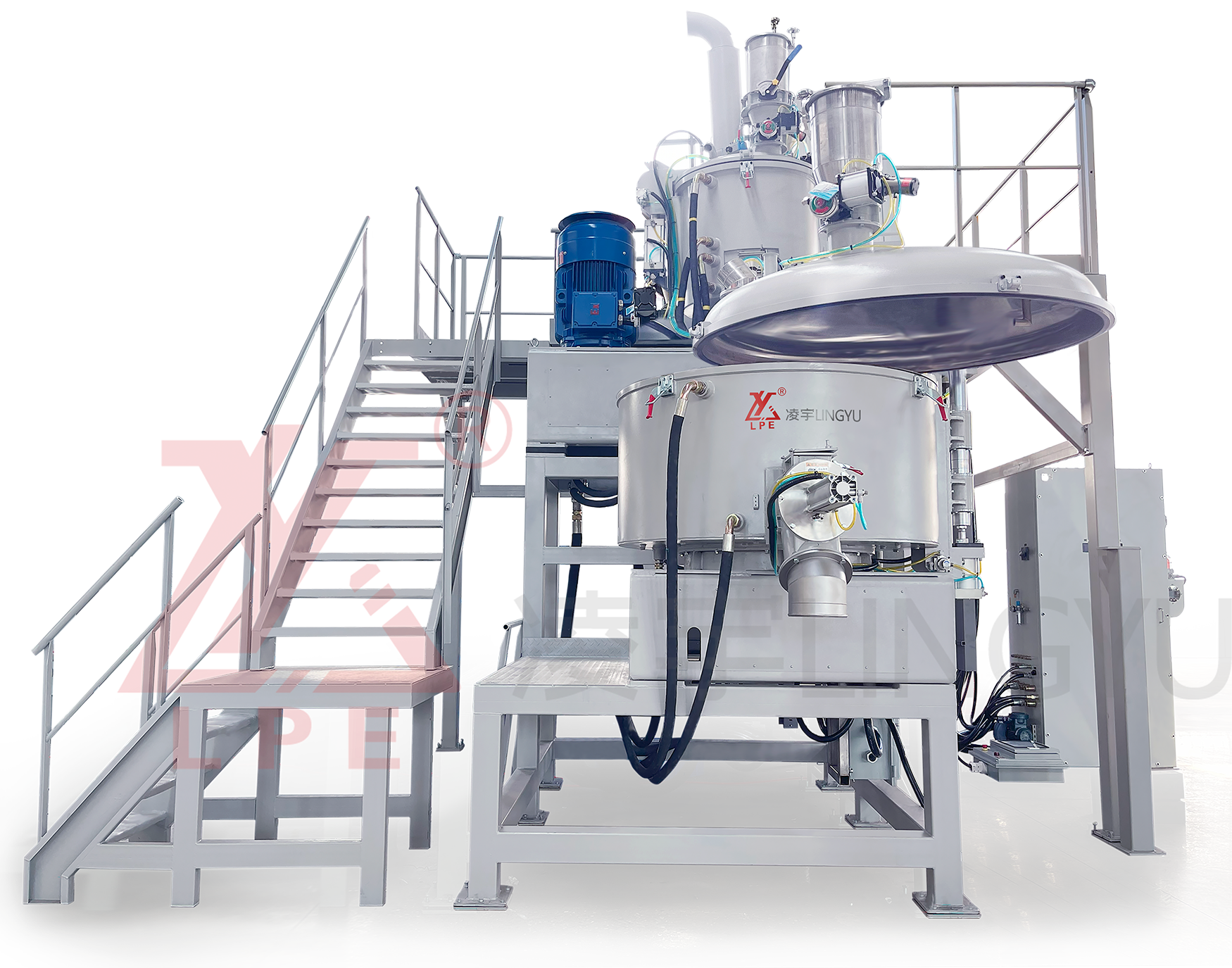

This equipment features an inert gas purging mixing tank and isequipped with an explosion-proof system and a double-sealingsystem. The bonding tank and cooling tank are equipped with a sand-dwich water cooling system. The tank body is designed with a large arc,and the angle and height of the baffles can be adjusted freely. It hasgood self-cleaning properties and provides uniform heating.

Fully Automated PLC Control: Real-time monitoring for enhanced precision and efficiency.

Explosion-Proof System: Oxygen concentration and nitrogen flow is monitored and controlled in real time, ensuring process safety.

Optimized Design & Temperature Control: Prevents material agglomeration for smooth bonding and consistent results.

Easy Maintenance & Operation: Reduces downtime, lowers maintenance costs, and enhances productivity.

Efficient Bonding & Quality Control: Guarantees high product quality and consistency throughout the process.

High Cooling Efficiency & Sealing Protection: Extends equipment lifespan and ensures operational reliability.

| Model | Hot Mixing Volume | Cold Mixing Volume |

Hot Mixing Motor(kW) |

Cold Mixing Motor(kW) | Cooling Medium | Gas | |

| MB-08 | 8 |

\ |

4 | \ |

Chilling Waters≤12° |

Inert Gas N2 |

|

| MB200/CM700 | 200 | 700 | 45 | 11 | |||

| MB350/CM1050 | 350 | 1050 | 90 | 15 | |||

| BDM500/DM1500 | 500 | 1500 | 132 | 22 | |||