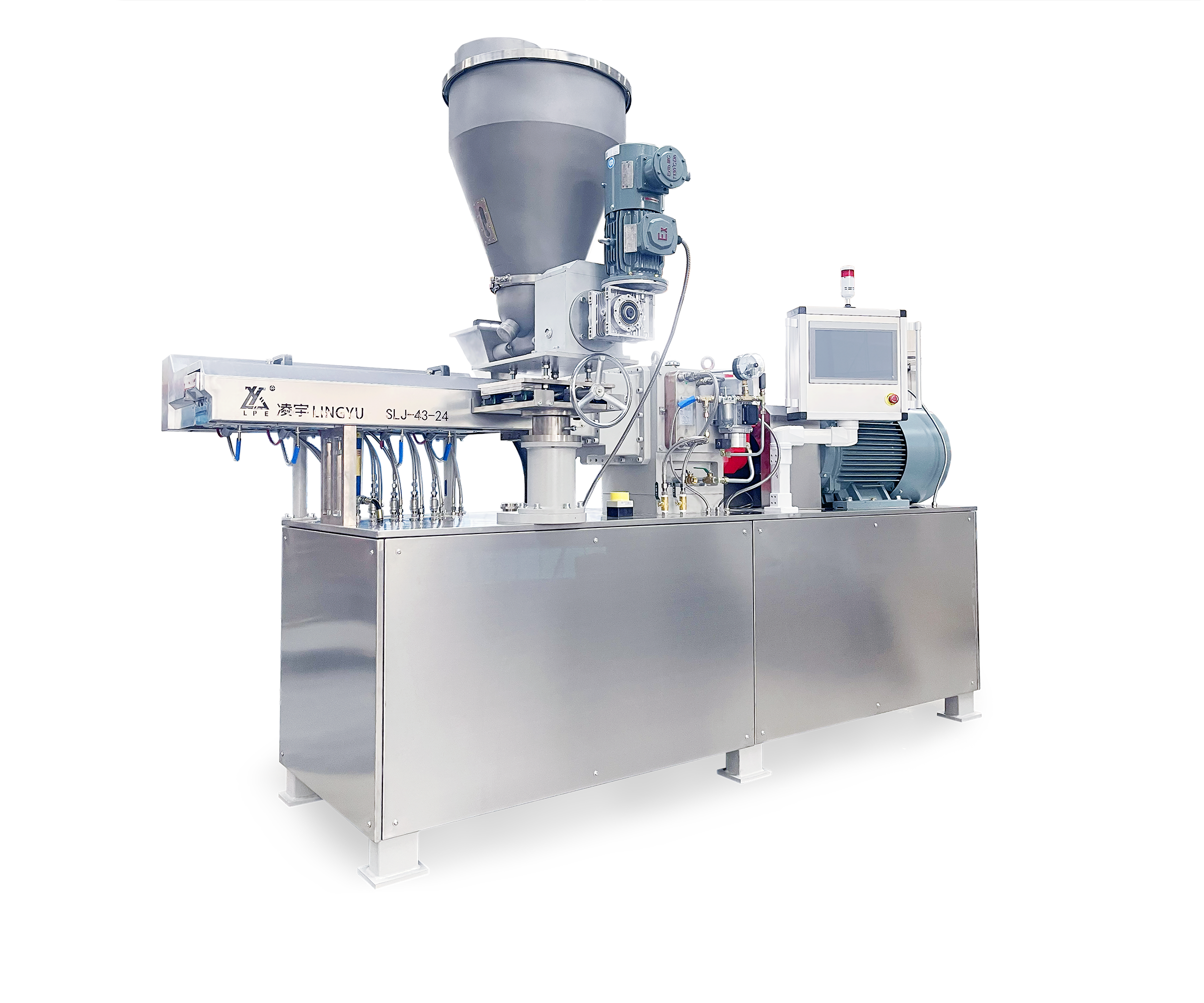

Lingyu SLJ Series Twin-Screw Extruders are designed with precision for powder coating production, supporting everything from pilot batches to continuous high-volume manufacturing. The system accommodates a wide range of formulations, such as polyester, epoxy, hybrid, and acrylic, `and also enables efficient reuse of reclaimed powder.

The 2025 SLJ-Pro upgrade brings higher speed, greater output, and enhanced process flexibility. Key components are manufactured in-house to ensure stable, long-term performance, and the gearbox is backed by a 5-year warranty, offering strong reliability and value for modern powder coating plants.

Customizable Screw & Kneading Elements: Optimized for various formulations.

Homogeneous Mixing: Clean-in-place design minimizes solidified particles.

Durable Gearbox: Independent lubrication and cooling for low noise and wear resistance.

Automated Control System: Real-time PLC monitoring for precision and efficiency.

Precision Temperature Control: Hydraulic modular barrel for easy cleaning and fast color changes.

Accurate Feeding: Anti-bridging device and metering screw ensure consistent dosing.

Main Technical Parameter

SLJ Series High- Speed Twin-Screw Extruder Technical Data

| Model | Output(kg/h) | Output Speed(rpm/min) | Single-Shaft Torque(N·m) | Operating Temperature(℃) | Driving Motor Power(kW) |

| SLJ-27 | 50 | 900 | 45 | 250 | 11 |

| SLJ-32 | 200 | 900 | 88 | 250 | 22 |

| SLJ-43 | 500 | 900 | 219 | 250 | 55 |

| SLJ-52 | 900 | 900 | 358 | 250 | 90 |

| SLJ-65 | 1200 | 900 | 525 | 250 | 132 |

| SLJ-75 | 1800 | 900 | 636 | 250 | 160 |

| SLJ-95 | 2500 | 900 | 759 | 250 | 200 |

SLJ Series Medium- Speed Twin-Screw Extruder Technical Data

| Model | Output(kg/h) | Output Speed(rpm/min) | Single-Shaft Torque(N·m) | Operating Temperature(℃) | Driving Motor Power(kW) |

| SLJ-27 | 40 | 600 | 18 | 250 | 4.4 |

| SLJ-32 | 120 | 600 | 30 | 250 | 7.5 |

| SLJ-43 | 300 | 600 | 147 | 250 | 37 |

| SLJ-52 | 500 | 600 | 179 | 250 | 45 |

| SLJ-65 | 700 | 600 | 219 | 250 | 55 |

| SLJ-75 | 1200 | 600 | 358 | 250 | 90 |

| SLJ-95 | 1800 | 600 | 525 | 250 | 132 |