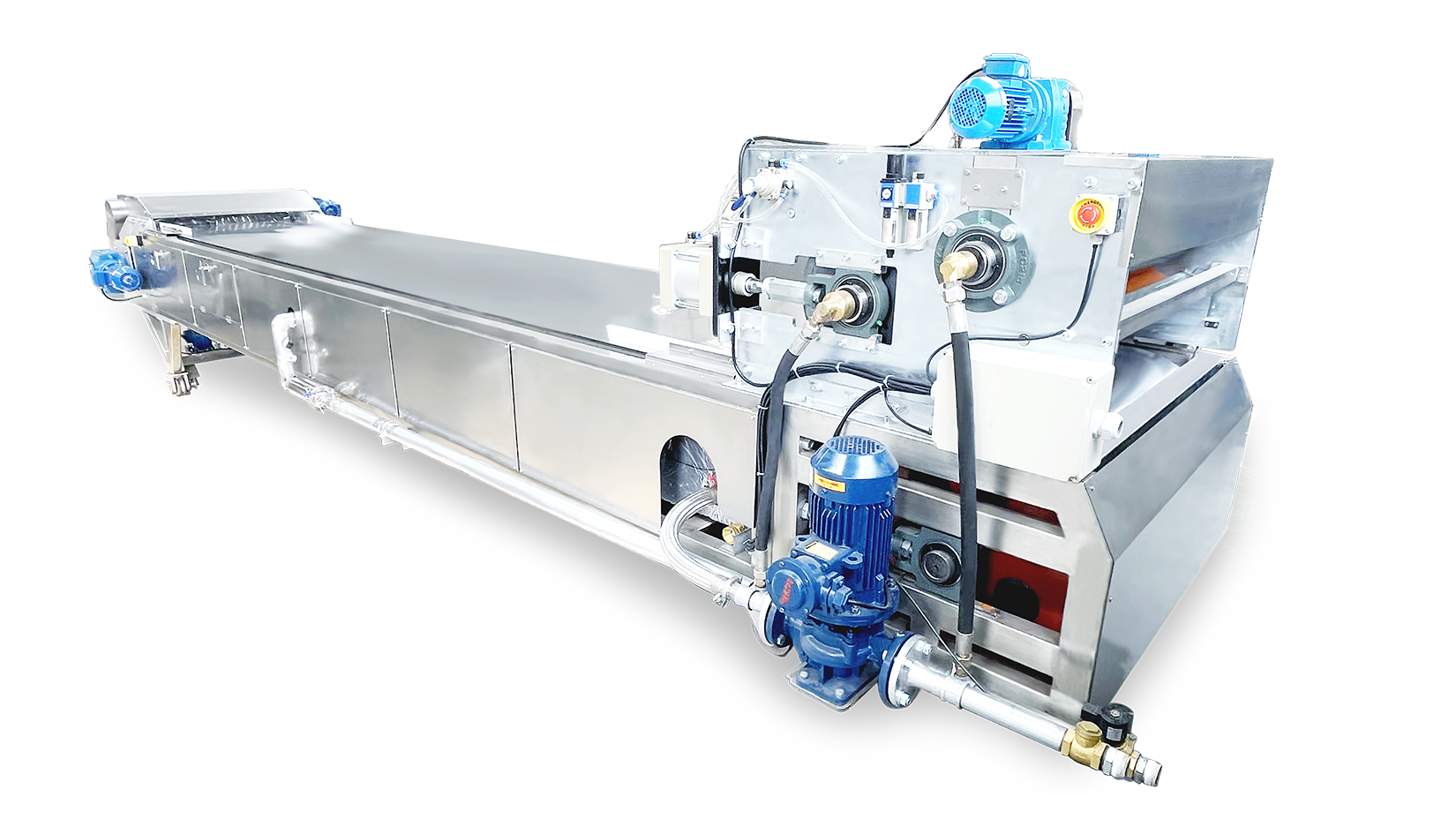

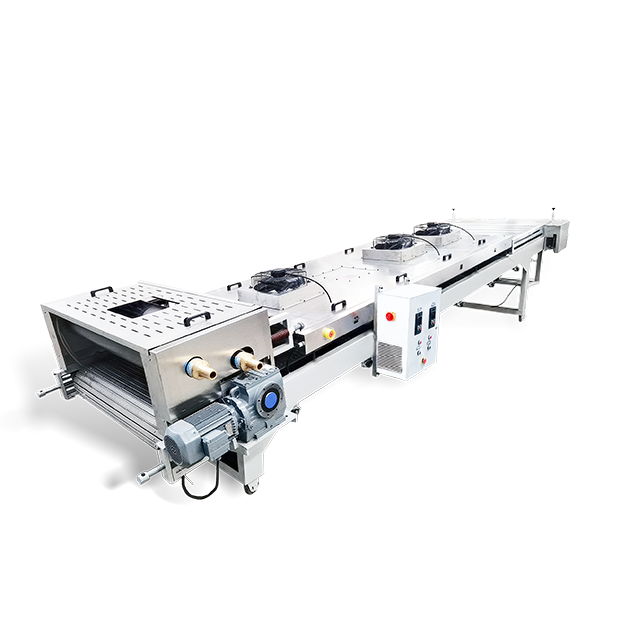

YPW Series Water Cooling Belt is composed of cooling rollers, stainless steel conveyor, crusher and cooling water spraying system. The cooling water spraying system is used to cool down stainless steel belt. The hot-melt materials from extruder are squeezed to thin sheet with thickness 1-2mm by cooling rollers, and being cooled down on the stainless steel conveyor to normal temperature, then being crushed into chips and discharged. This series of cooling belt can meet the output requirements from lab scale to utmost production, which makes it an ideal equipment for chips production.

YPW steel belt cooler is composed of cooling rollers, stainless steel conveyor, crusher and cooling water spraying system. The cooling water spraying system is used to cool down stainless steel belt. The hot-melt materials from extruder are squeezed to thin sheet with thickness 1-2mm by cooling rollers, and being cooled down on the stainless steel conveyor to normal temperature, then being crushed into chips and discharged. This series of cooling belt can meet the output requirements from lab scale to utmost production, which makes it an ideal equipment for chips production.

Durable Stainless-Steel Frame: Ideal for water-cleaning environments.

Consistent Chip Size: Adjustable thickness and roller speed for precise control.

Clean Cooling System : Uses cold water to prevent contamination.

Enhanced Safety : Equipped with an emergency stop and reverse function.

Main Technical Parameter

| Model | Belt Effective Length (mm) | Belt Effective Width (mm) | Output(kg/h) | Main Power(kW) | Dimension(mm) |

| YPW-526 | 2600 | 500 | 50-100 | 0.55-0.75 | 4000×1200×1600 |

| YPW-640 | 4000 | 600 | 120-180 | 1.1-1.5 | 5000×1300×1600 |

| YPW-850 | 5000 | 800 | 200-300 | 1.5-2.2 | 6000×1500×1800 |

| YPW-1070 | 7000 | 1000 | 350-600 | 1.5-2.2 | 8000×1700×2000 |

| YPW-1270 | 7000 | 1200 | 700-800 | 2.2-3.0 | 8000×1900×2000 |

| YPW-1570 | 7000 | 1200 | 900-1000 | 3.0-5.5 | 8000×2100×2000 |