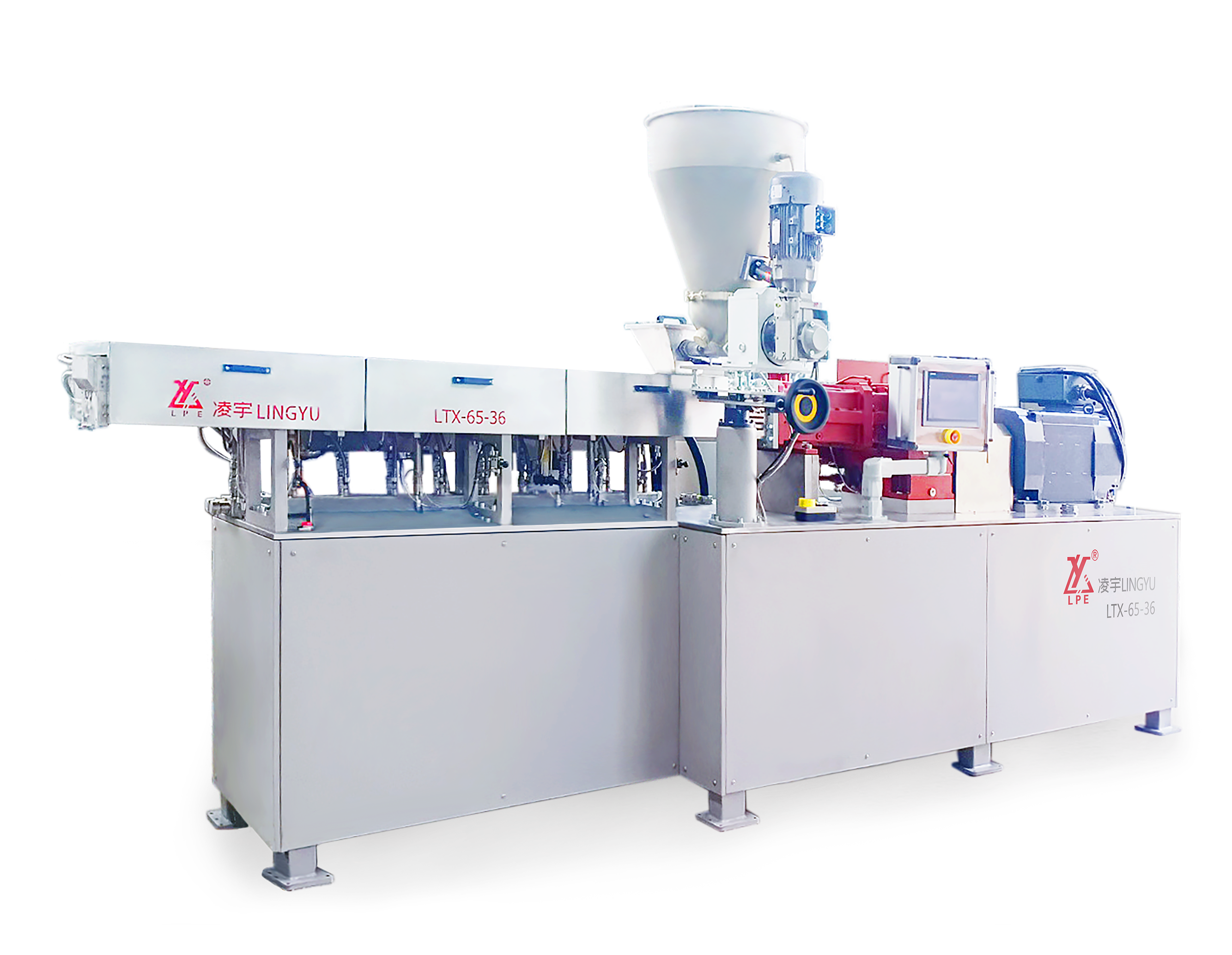

The LTX Series Extruders are equipped with a range of advanced features, including an optimized Do/Di ratio, a high-torque gearbox, higher screw speeds, and twin-screw side feeding. These technologies ensure that materials achieve thorough dispersion and uniform mixing at lower processing temperatures, thanks to the high-speed operation of precision kneading elements. This allows the LTX series to meet the demands of higher-performance powder coating products.

Modular screw sleeves and kneading

components enable flexible assembly,

catering to diverse formulation

production requirements.

Smart Software: Integrated recipe and maintenance management.

Optimized Do:Di Ratio: Maximizes free volume and production efficiency.

Advanced Feeding System: Adaptable to multiple feeding systems.

Self-Cleaning Screw Design: Prevents particle solidification for long-term reliability.

Adaptive Production Modes: Warm-up, standby, and full-speed production modes for flexibility.

Precision Temperature Control: PID-regulated heating and cooling within ±2°C.

Flexible L/D Ratio: In 3D/6D standard increments to suit all formulations.

The 16:1 length-to-diameter ratio series is designed for handling textured powders and epoxy powders (fast-reacting type)

| Model | Output(kg/h) | Output Speed(rpm/min) | Single-Shaft Torque(N·m) | Operating Temperature(℃) | Driving Motor Power(kW) |

| LTX-27 | 50-100 | 900-1200 | 60 | 250 | 11-15 |

| LTX-33 | 150-300 | 900-1200 | 88 | 250 | 18.5-22 |

| LTX-44 | 500-800 | 900-1200 | 298 | 250 | 55-75 |

| LTX-53 | 800-1000 | 900-1200 | 438 | 250 | 90-110 |

| LTX-66 | 1000-1600 | 900-1200 | 637 | 250 | 132-160 |