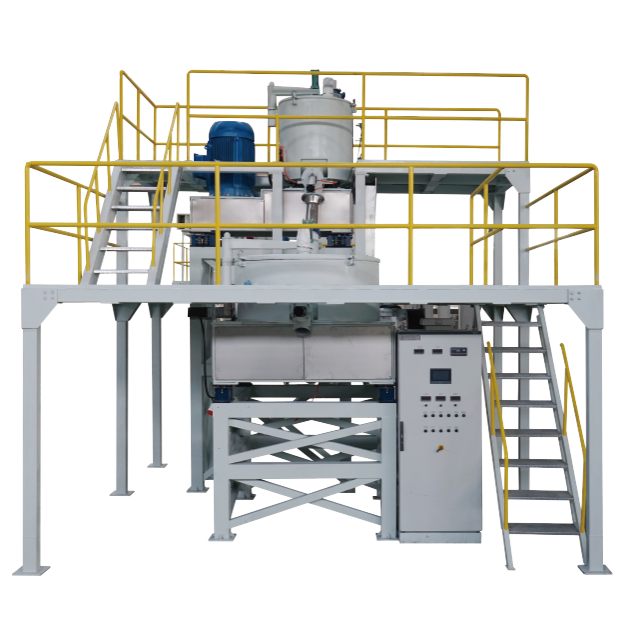

BDM Series Metallic Bonding Mixer is a speciallised equipment to bond the metallic pigment to the surface of powder coating granules to achieve the metallic finish.

Bonding and cooling container are equipped with sandwich water cooling system

The container adopts large arc design with good self-cleaning property.

Equipped with baffle plate whose adjustable angle and height ensuring even temperature during the heating process

The discharge is controlled by pneumatic valve,ensuring thorough discharge, avoiding cross contamination.

All bonding process adopts automatic control system

PLC / touch screen automatic control, real-time display equipment operation

The mixing container is blow-washed by inert gas, equipped with explosion-proof system and double sealing system

Clamshell type opening, cylinder hinge open, convenient cleaning

Optional N2 generator

| Model | Hot Mixing Volume(L) | Cold Mixing Volume |

Hot Mixing Power(kW) |

Cold Mixing Power | Cooling Medium | Gas | |

| BDM200/DM600 | 200 | 600 | 45 | 11 | |||

| BDM350/DM1000 | 350 | 1000 | 75 | 18.5 |

Chilling Water≤12° |

Inert Gas N2 |

|

| BDM500/DM1500 | 500 | 1500 | 90 | 22 | |||